0577-88630038

current location:home page > About Runxin > Company News

Source: Runxin Popularity: dateline:[2021-08-19] 【 小 中 大 】

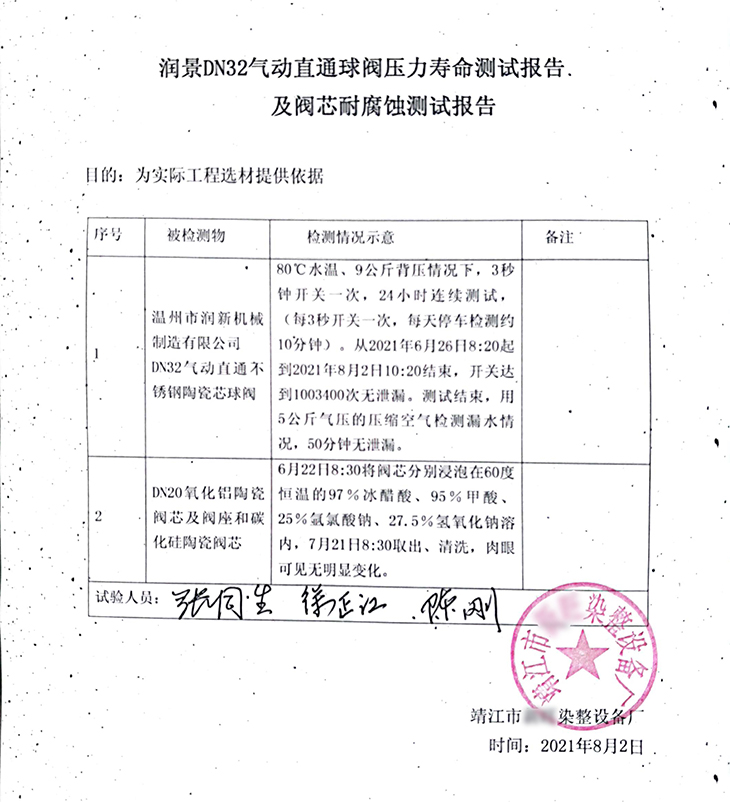

At the end of June this year, a dyeing and finishing equipment factory in Jiangsu conducted lifetime test and corrosion resistance test on Runjing ceramic ball valve, valve core and valve seat respectively, and recently completed the test.

Under the condition of water temperature of 80 ℃ and pressure of 9kgf / cm2, open and close once every 3 seconds, conduct continuous test for 24 hours, and open and close 1003400 times without leakage!

Under the condition of constant temperature of 60 ℃, Runjing ceramic valve core and valve seat can resist the corrosion of glacial acetic acid, formic acid and sodium chlorite.

Lifetime Test

Test conditions

Medium: Tap water

Water temperature: 80 ℃

Pressure: 9kgf / cm2

Test frequency: Open and close once every 3 seconds, continuously

Runjing ball valve model: DN32 pneumatic ball valve with ceramic core and stainless steel valve body

Test start time: June 26th, 2021 08:20am

By 10:20 on August 2nd, DN32 pneumatic ball valve with ceramic core and stainless steel valve body had been tested continuously for 24 hours under the condition of 80 ℃ water temperature and 9kgf / cm2 water pressure, and 1003400 times of opening and closing without leakage. Then close the valve, use compressed air with air pressure of 5kgf / cm2 to detect the leakage, observe for 50 minutes, and no leakage was found.

Corrosion Resistance Test

Test conditions

Medium: 97% glacial acetic acid, 95% formic acid and 25% sodium chlorite solution

Solution temperature: 60 ℃

Test parts: Runjing ceramic valve core and valve seat (made of alumina and silicon carbide)

Test start time: June 22th, 2021 08:30am

Under the condition of constant temperature of 60 ℃, the ceramic valve core and valve seat are immersed in 97% glacial acetic acid, 95% formic acid and 25% sodium chlorite solution for 1 month. At 8:30 of July 21th, take out, clean and dry the soaked ceramic valve core and valve seat.

Runxin company obtained the ceramic valve core and valve seat tested this time, and found that the hardness and quality of ceramic valve core and valve seat had no obvious change

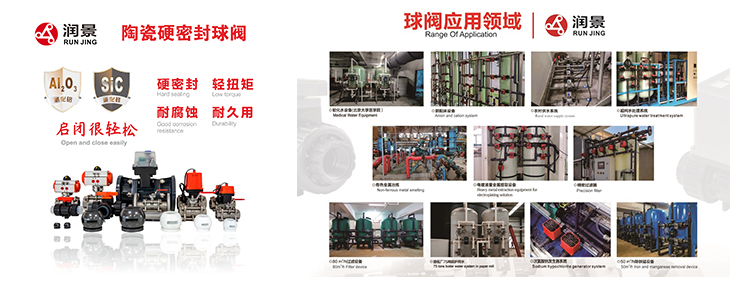

The core component of Runjing ceramic ball valve,the valve core and valve seat, is made of corundum ceramic or silicon carbide material, is sintered at 1680 ℃ or 2200 ℃ at ultra-high temperature. The Rockwell hardness HRA is more than 85 °. At the same time, it has the characteristics of "low torque, good corrosion resistance, good wear resistance and durability". It can solve many problems that are difficult to be solved by traditional valves. It is suitable for hydrochloric acid, sulfuric acid, sodium hydroxide, seawater, industrial wastewater and other acids, alkalis and special media.

At present, Runjing ceramic ball valve has been gradually popularized and used in China, with good market response, and exported to 24 countries and regions. It is widely used in water desalination, papermaking, printing, electroplate, melting, energy, chemical medical, intelligent liquid controlling, card type water meter, sewage water treatment, etc.

The dyeing and finishing equipment factory has purchased several sets of Runjing ball valves for pipeline automatic metering and dosing equipment, and purchased DN32 pneumatic ball valve for life test at the beginning of this year. The test results show that under the condition of water pressure of 1.6kgf/cm2, the switches have been opened and closed for more than one million times without leakage.

Engineer Zhang, the factory's test director, said that the sealing and corrosion resistance of Runjing ball valve meet the engineering requirements of the factory. Engineer Zhang was very satisfied with both the life test at the beginning of the year and the corrosion resistance and pressurization life test this time. He believed that even if the test was continued, Runjing ceramic ball valve would still not leak.