0577-88630038

current location:home page > Download > Application Case

Source: Runxin Popularity: dateline:[2022-07-29] 【 小 中 大 】

The boiler cannot operate without water, and the quality of water directly affects the safe operation and service life of the boiler.Therefore, good boiler water treatment is an important precondition to ensure the safe and economic operation of the boiler. For this purpose, China has specially formulated national standard for boiler water which are regularly revised and upgraded, the current Chinese standard is GB/T 1576-2018 “Water quality for industrial boilers”.

Condensate water recycling system is an emerging technology that has developed rapidly in recent years. It can effectively put a large amount of heat energy contained in condensate into steam boiler makeup water again, to reduce the heat consumption required when makeup water is heated up. It can not only greatly reduce the use of fuel and electricity, but also save water resources and achieve the purpose of energy conservation and emission reduction.

Runjing ceramic hard seal stainless steel electric ball valve has great advantages in the condensate recycling system. Its valve body and shaft are made of 316L stainless steel, and the valve core is made of good wear resistant, good heat resistance and good corrosion resistant special ceramics. And the distance between the electric actuator and the valve body is lengthened to fully dissipate heat to ensure the stable operation of the actuator. Many years of practice proved that Runjing stainless steel electronic valve is suitable for condensate water recycling filtration, iron removal system.

The condensate water recycling system is mainly to deal with trace iron ions produced in the condensed water flowing through the iron pipe and some hardness ions infiltrated along the process to ensure the water quality of the boiler reuse water.

Process flow of condensate water recycling sodium ion iron removal exchanger system: condensate water→ condensate water tank→ variable frequency pump→ filtration system→ iron removal, softening system (regeneration system) →deoxidized system→ deoxidized system water tank→ boiler make up pump→ boiler system.

Condensate water recycling filtration, sodium ion iron removal and softening exchanger system is composed of full-automatic filter and full-automatic sodium ion iron removal and softening exchanger in series.

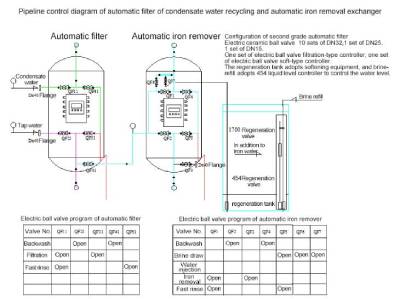

Installation diagram of condensate water recycling sodium ion iron removal exchanger system.

Note: the water for backwash of automatic filter and the salt water of automatic iron removal softener are all qualified softened water.

20~30m³/h condensate water recycling full-automatic filter

It consists of a DN1500 Q235 steel exchange tank coated with heat resistance and anti-rot material, a Runjing F109 ball valve controller, a set of 304 stainless steel side mounted top and bottom strainer, a sampling valve, a pressure gauge, 3000kg fine quartz sand, drain pipeline, and a set of DN65/50 PPH heat resistant internal connection filter pipeline.

Control composition: one set Runjing F109 ball valve controller, five sets Runjing DN65/50 stainless steel 316L electronic ball valves, and PPH heat resistant internal connecting pipeline.

The system in strict accordance with requirements of GB/T18300-2011“Specification for automatic control sodium ion exchange” optimization design, and has the function of filtration, backwash and fast rinse. The time of filter, backwash and fast rinse can be set through F109 ball valve controller, and the control program can be modified at any time according to the effluent quality. In order to ensure the effluent quality of subsequent equipment is qualified, the water of backwashing is softened water, and the filtered water is directly used for subsequent iron removal and softener.

20~30m³/h condensate water recycling sodium ion iron removal and softening exchanger

It consists of a DN1200 Q235 steel exchange tank coated with heat resistance and anti-rot material, a Runjing F109 ball valve controller, a set of 316 stainless steel side mounted top and bottom strainer, a 1500L salt tank, a 1700 brine valve (for brine), a 454 brine valve (for brine refill), a sampling valve, a pressure gauge, 1200kg cation exchange resin, brine pipe and drain pipe, and a DN65/50 PPH heat resistant internal connection pipeline system.

Control composition: one set Runjing F109 ball valve controller, seven sets Runjing DN65/20 stainless steel electronic ball valves, and a injector for heat resistant regeneration.

According to the requirements of “Specification for automatic control sodium ion exchange” GB/T18300-2011 in China, combined with different water capacity design, the condensate water recycling sodium ion iron removal and softening exchanger can be deeply softened while normal iron removal.

Installation diagram of condensate water recycling equipment

Technical feature of condensate water recycling sodium ion iron removal exchanger system:

(1) High flow rate, no need to heat, supply water can remove iron ions, calcium and magnesium ions.

(2) Wide subject range, it is applicable to condensate water with iron ion content 10mg/L, hardness 300mg/L.

(3) The operation cost is low, only industrial salt is consumed, and the cost is very low.

(4) The sodium ion exchange technology is mature, and the outlet water quality is stable and reliable.

(5) Small volume, low installation height, convenient operation and strong practicability.

(6) The sodium ion exchanger is refined from environmental protection and energy-saving materials, and the equipment has high performance stability.

Operating principle of condensate water recycling sodium ion iron removal exchanger system:

When the water containing iron ions enters the cation resin exchange layer, it immediately reacts with the sodium-type cation exchange resin: the iron ions in the water are adsorbed by the resin, and the sodium ions are exchanged into the filtered water, thus completing the iron removal process. Its chemical equation is as follows:

Fe 2+ + NaR = FeR + Na +

When the water containing calcium and magnesium ions enters the cation resin exchange layer, it immediately replacement reactions with sodium-type cation exchange resin after iron removal: the calcium and magnesium ions in water are absorbed by the resin and the sodium ions are exchanged, thus completing the deep softening process. Its chemical equation is as follows:

Ca 2+ + NaR = CaR + 2Na

Mg 2+ + NaR = MgR + 2Na

When the resin fails to operate, the exchanged capability of the resin can be restored by using industrial salt regeneration.

Technical index of cation exchange resin of condensate water recycling sodium ion iron removal exchanger system.

Total exchange capacity: 1800mol/m3

Working Exchange Capacity: 900mol/m3

Particle size range: 20-30 mesh

Bulk density: 800kg/m3

Moisture content: 45-55%

Whole beads count: 98%

Main ingredients: styrene

Application condition of condensate water recycling sodium ion iron removal exchanger system.

A. Water qualifies condition of water source

Iron ion:<10mg/L

Total hardness:<0.6mmol/L(300mg/L CaCO3)

Suspended solids:<5mg/L Water temperature:<100°C

B. Pressure conditions of water source

Water pressure:0.24-0.35MPa

Test standards and methods

Standard: China GB/T1576-2018 Water quality for industrial boiler

Method: EDTA complexometric

Standard:China GB/T1576-2018 Water quality determination of iron ion for industrial boiler

Method: Potassium thiocyanate method

Runjing F109A ball valve controller adopts microcomputer program control technology and is suitable for Runjing DN15-DN80 electronic ball valve, it has the functions of filter, backwash, fast rinse, down/up-flow regeneration, brine& slow rinse, brine refill (raw water or soft water), immediate regeneration, delayed regeneration, one in service one standby, RS-485 communication etc., the softening water treatment cycle and fast rinse, backwash, brine& slow rinse, brine refill time can be set according to the water quality conditions.

Runjing stainless steel electronic ball valve has characteristic of good wear resistance, impurity resistance, good heat resistance, good corrosion resistance, low torque, low flow resistance, water hammer resistance, which suitable for different water source working conditions and service conditions.

Runjing F109 ball valve controller is combined with Runjing electronic ceramic ball valve to form a water treatment system, which can be used in parallel to meet requirement of 0.5-500m³/h filter and softener water treatment equipment, it has incomparable advantage in congeneric product at home and abroad.

The content of this article is for reference only, and the system configuration can be adjusted according to the actual situation.